Barite, a naturally occurring mineral composed of barium sulfate (BaSO₄), plays an essential role in the oil and gas drilling industry. Its primary use is as a weighting agent in drilling mud, a fluid mixture used during the drilling of wells to ensure operational efficiency and safety.

1. Weighting Agent

Barite's high specific gravity (typically 4.2–4.5 g/cm³) makes it ideal for increasing the density of drilling fluids. Properly weighted mud prevents the influx of formation fluids, controls subsurface pressures, and reduces the risk of blowouts.

2. Maintaining Wellbore Stability

The addition of barite helps maintain hydrostatic pressure in the wellbore. This pressure balances the formation pressures, preventing collapse or caving of the borehole walls and ensuring the structural integrity of the well.

3. Minimizing Fluid Loss

Barite contributes to the rheological properties of drilling mud. By adjusting viscosity and density, it helps minimize fluid loss into porous rock formations, reducing potential damage to the reservoir and optimizing drilling efficiency.

4. Enhancing Drilling Performance

Barite's chemical inertness ensures it does not react with other components in the mud or the formation. This stability allows for smoother drilling operations, reduced equipment wear, and lower maintenance costs.

5. Environmental Safety

As a non-toxic mineral, barite is safe to handle and environmentally benign, making it a preferred choice in formulating drilling fluids compared to other synthetic additives.

Conclusion

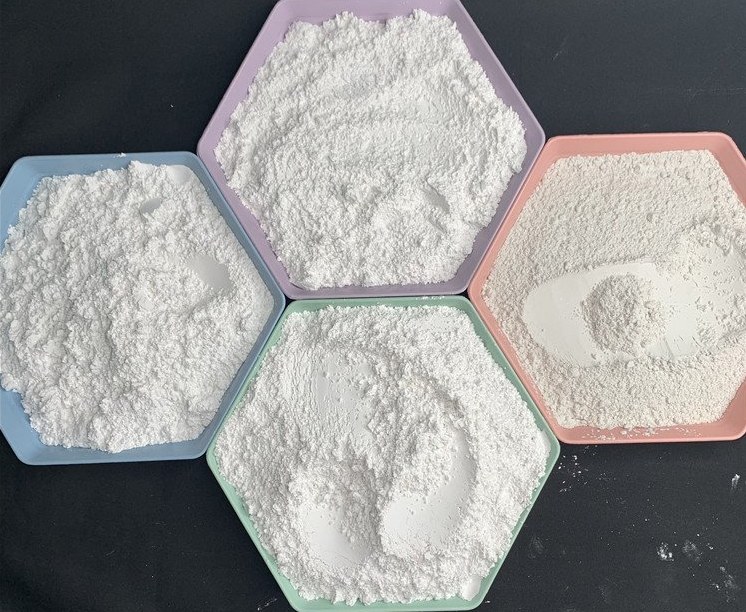

Barite powder is indispensable in the drilling process. Its high density, chemical stability, and inert properties make it the go-to mineral for maintaining wellbore stability, controlling formation pressure, and improving overall drilling efficiency.

FAQ

Q1: What is the typical particle size of barite used in drilling mud?

A: Barite is usually ground to a particle size of 325 mesh (around 44 microns) to ensure proper suspension in drilling fluids.

Q2: Can barite be replaced by other minerals in drilling mud?

A: While other materials like hematite or calcium carbonate can be used, barite remains preferred due to its high density, chemical stability, and cost-effectiveness.

Q3: How much barite is typically added to drilling mud?

A: The amount varies depending on the required mud weight, usually between 10% to 50% by volume of the mud.