Japan's rubber and tire manufacturing industry is recognized worldwide for its strict quality standards, advanced technology, and focus on product consistency. Carbon black is a critical raw material in this sector, widely used as a reinforcing filler in tires, industrial rubber products, seals, hoses, and automotive components. The performance of carbon black in rubber compounds depends heavily on particle size, dispersion uniformity, and surface characteristics, all of which are directly influenced by the grinding process.

To meet the demanding requirements of Japanese rubber and tire manufacturers, a reliable carbon black grinding mill must deliver ultra-fine, stable powder with minimal contamination and high production efficiency. Selecting the right grinding equipment is therefore a key investment decision, especially for producers seeking factory direct international shipping and long-term operational stability.

The Importance of Carbon Black Grinding Quality

Carbon black is produced through incomplete combustion or thermal decomposition of hydrocarbons, resulting in fine particles with high surface area. While primary carbon black particles are extremely small, agglomerates often form during production and handling. Grinding plays a crucial role in breaking down these agglomerates and achieving a controlled particle size distribution suitable for rubber compounding.

In tire production, properly ground carbon black improves tensile strength, abrasion resistance, tear resistance, and durability. Inconsistent grinding can lead to poor dispersion, uneven mechanical properties, and reduced product lifespan. For Japanese manufacturers, where precision and reliability are essential, grinding equipment must operate with exceptional stability and accuracy.

Challenges in Carbon Black Grinding

Grinding carbon black presents unique technical challenges. The material is lightweight, highly dispersible, and prone to dust generation. It can also adhere to equipment surfaces and affect grinding efficiency if not properly managed. Common challenges include:

Achieving ultra-fine particle sizes without excessive energy consumption

Maintaining consistent fineness over long production cycles

Controlling dust emissions to ensure a clean and safe working environment

Reducing wear and maintenance costs caused by continuous operation

These challenges make advanced grinding technology essential for carbon black processing, particularly for high-end rubber and tire applications.

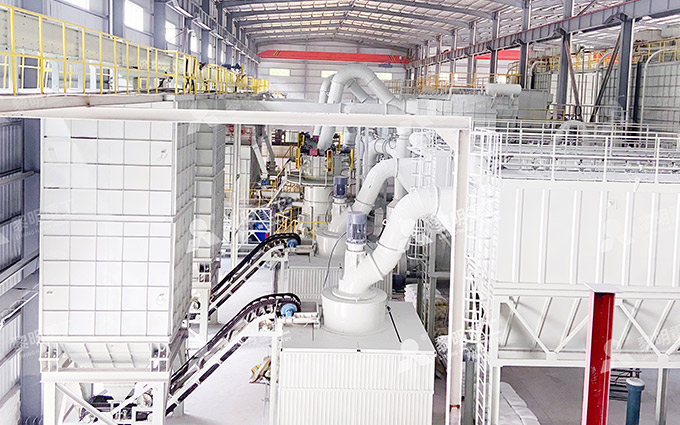

Advanced Grinding Solutions from Liming Heavy Industry

Liming Heavy Industry provides specialized grinding solutions for carbon black processing, designed to meet the needs of rubber and tire manufacturers in Japan. With extensive experience in fine powder grinding technology, Liming's equipment focuses on efficiency, precision, and long-term reliability.

Among the available options, modern vertical grinding mills and micro powder grinding systems stand out as ideal choices for carbon black production. These mills are engineered to handle fine, lightweight materials while maintaining stable output and low energy consumption.

Carbon Black Vertical Grinding Mill

The vertical grinding mill is well suited for large-scale carbon black production lines serving tire and rubber factories. Its integrated grinding and classification design allows for precise control of particle size and consistent product quality.

High Grinding Efficiency: The vertical mill uses grinding rollers and a rotating table to apply uniform pressure, ensuring effective size reduction of carbon black agglomerates.

Stable Particle Size Control: Advanced classifiers enable accurate adjustment of fineness to meet different rubber compound requirements.

Lower Energy Consumption: Optimized grinding mechanics reduce power usage per ton of finished product.

Clean Operation: Enclosed structure and efficient dust collection systems minimize powder leakage and environmental impact.

For Japanese manufacturers focusing on continuous, high-volume production, the vertical mill offers a strong balance between output capacity and operational cost control.

Micro Powder Grinding Mill for Ultra-Fine Carbon Black

For applications requiring extremely fine carbon black powder, such as high-performance tires and specialty rubber products, a micro powder grinding mill provides enhanced fineness control. This type of mill is designed to produce powder in the micron and sub-micron range with excellent uniformity.

Ultra-Fine Grinding Capability: Suitable for producing carbon black powder with high surface area and improved dispersion.

Precise Classification: Multi-stage classification ensures tight particle size distribution.

Reduced Heat Generation: Optimized airflow design prevents overheating and preserves material properties.

Flexible Capacity: Adaptable to small and medium production lines or specialized applications.

This solution is ideal for manufacturers in Japan who prioritize premium product performance and strict quality control.

Applications in Japan's Rubber and Tire Industry

Ground carbon black produced by advanced grinding mills is used across a wide range of rubber and tire applications in Japan, including:

Passenger car and truck tires

High-performance and specialty tires

Industrial rubber products and conveyor belts

Automotive seals, gaskets, and vibration-damping components

Consistent grinding quality ensures uniform dispersion of carbon black in rubber compounds, resulting in predictable mechanical properties and improved production efficiency for downstream processing.

Factory Direct International Shipping to Japan

Liming Heavy Industry offers factory direct international shipping, allowing Japanese customers to source grinding equipment directly from the manufacturer. This approach reduces intermediary costs and ensures transparent communication throughout the project lifecycle.

Equipment is carefully packaged for long-distance transportation and shipped according to international standards. Detailed documentation and technical support are provided to facilitate smooth customs clearance and on-site installation in Japan.

Customization and Technical Support

Every carbon black grinding project has unique requirements, including target fineness, production capacity, plant layout, and environmental standards. Liming Heavy Industry provides customized solutions based on detailed project analysis.

Technical support covers equipment selection, process design, installation guidance, commissioning, and operator training. This comprehensive service approach helps customers achieve stable production quickly and maintain long-term efficiency.

Economic and Environmental Advantages

Investing in an advanced carbon black grinding mill offers significant economic benefits. High grinding efficiency and low energy consumption reduce operating costs, while durable components minimize maintenance expenses and downtime.

From an environmental perspective, modern grinding systems with efficient dust collection contribute to cleaner production environments. This is particularly important in Japan, where environmental regulations and workplace safety standards are among the most stringent in the world.

Conclusion

For rubber and tire production in Japan, carbon black grinding quality plays a decisive role in product performance and manufacturing efficiency. Advanced grinding mills from Liming Heavy Industry provide reliable, efficient, and precise solutions tailored to the needs of modern rubber processing plants.

With factory direct international shipping, customized configurations, and professional technical support, these grinding systems help Japanese manufacturers achieve consistent carbon black quality while maintaining cost control and environmental compliance.

Frequently Asked Questions

1. Why is fine grinding important for carbon black in tire production?

Fine and uniform carbon black improves dispersion in rubber compounds, enhancing strength, abrasion resistance, and overall tire performance.

2. Which grinding mill is better for large-scale carbon black production?

Vertical grinding mills are ideal for large-scale, continuous production due to their high efficiency and stable output.

3. Can ultra-fine carbon black be produced for high-performance tires?

Yes, micro powder grinding mills can produce ultra-fine carbon black with precise particle size control.

4. How is dust controlled during carbon black grinding?

Modern grinding systems use enclosed structures and high-efficiency dust collectors to minimize emissions and maintain a clean environment.

5. Is factory direct shipping suitable for delivery to Japan?

Factory direct international shipping is well suited for Japan, with professional packaging, documentation, and technical support ensuring smooth delivery and installation.