Calcium carbonate is one of the most widely used mineral fillers in plastic, paint, and coating industries across India. Its availability, cost effectiveness, and ability to enhance product performance have made it indispensable for manufacturers seeking improved rigidity, opacity, surface finish, and dimensional stability. However, the quality of ground calcium carbonate depends heavily on the choice of grinding mill, as particle size, distribution, and shape directly influence the end application's performance. Selecting the right grinding mill can determine product competitiveness, energy consumption, and long-term profitability.

Understanding the Requirements of End-Use Applications

Before deciding on grinding equipment, it is important to understand the specific requirements of each industry. In plastic applications, calcium carbonate acts as a reinforcing filler that improves stiffness, heat deflection temperature, and impact strength. Plastic processors often require a controlled particle size distribution, typically between 1 µm and 5 µm, to ensure good dispersion without adversely affecting melt flow and surface gloss.

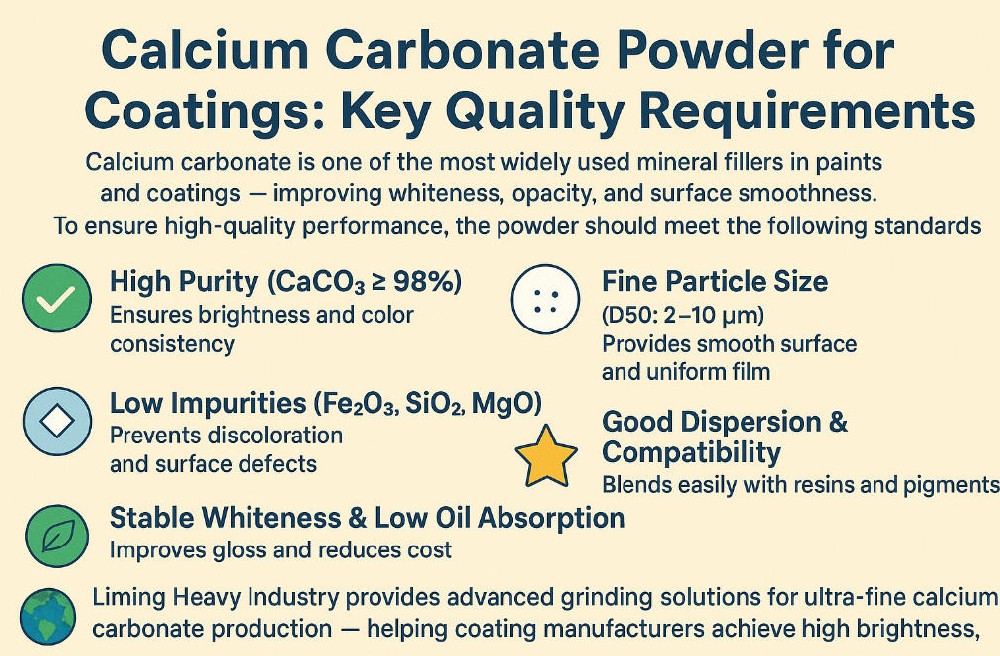

In paints and coatings, calcium carbonate improves opacity, brightness, and coverage while helping control viscosity and rheology. For decorative paints, a moderate fineness often suffices, but high-performance coatings, industrial coatings, and automotive paints demand finer particles down to 1 µm or below to achieve smooth appearance and optimal binder utilization. These differing demands make the selection of grinding technology critical for consistent product quality.

The Importance of Particle Size and Shape

Particle size and shape are key attributes that affect the functionality of calcium carbonate in plastics, paints, and coatings. Fine particles increase surface area, which enhances interaction with polymer matrices and binders. Uniform particle shape improves packing density, reduces voids, and promotes consistent mechanical and optical properties. Irregular or oversized particles can cause defects such as haziness in plastics, poor finish in coatings, and uneven texture in paints.

Grinding mills used for calcium carbonate must achieve the targeted fineness while maintaining narrow particle size distribution. In addition, the equipment should minimize excessive heat generation to preserve chemical stability and prevent agglomeration.

Comparing Grinding Technologies

There are several grinding technologies available for calcium carbonate production in India, each with its strengths and limitations. Three common options to consider are Raymond mills, vertical roller mills, and ultrafine grinding mills. Liming Heavy Industry has been a trusted provider of industrial milling equipment, offering solutions that meet the varied needs of plastic, paint, and coating manufacturers.

The Raymond mill is a traditional, well-proven grinding solution suited for medium and fine powder production. It offers stable performance, relatively low capital cost, and simple operation. For calcium carbonate applications where particle sizes in the range of 10 µm to 75 µm are acceptable, a Raymond mill provides an economical choice.

In the plastic industry, a Raymond mill can produce fillers that improve rigidity and reduce manufacturing costs without compromising processability. For certain paint applications, especially decorative and general-purpose paints, the fineness achieved by a Raymond mill is adequate and assures smooth application and good coverage.

Furthermore, Liming Heavy Industry's Raymond mills are designed with optimized grinding rollers, efficient classifiers, and improved sealing systems. These features reduce energy consumption, control dust emissions, and extend component life—important considerations for Indian manufacturers dealing with varying raw material characteristics and operational conditions.

Vertical Roller Mill

For larger production capacities and tighter control over particle size distribution, a vertical roller mill is often preferred. This type of mill integrates grinding, drying, and separation into a single system, reducing equipment footprint and operational complexity. Vertical roller mills are capable of producing calcium carbonate with finer and more consistent particle size compared to traditional mills.

In paint and coating applications, vertical roller mills help ensure the uniformity and brightness needed for high-quality finishes. The equipment's high grinding pressure and efficient classification system enable reliable production of powders with particle sizes down to a few microns. Plastic manufacturers benefit from improved filler properties that enhance composite material strength, reduce wear on processing equipment, and allow for higher filler loadings without sacrificing performance.

Liming Heavy Industry's vertical roller mills come equipped with advanced hydraulic systems and high-efficiency separators, enabling quick adjustments to fineness based on product specifications. These mills are also designed for energy efficiency, which helps control operating costs in India's competitive manufacturing environment.

For applications demanding extremely fine calcium carbonate particles, such as specialty coatings, premium paints, and high-performance plastic compounds, ultrafine grinding mills are often the best choice. These mills use high-speed impact and advanced classification technologies to achieve particle sizes below 2 µm with narrow distribution and consistent shape.

Ultrafine calcium carbonate provides superior dispersion properties, improved opacity, and enhanced mechanical strength, making it ideal for premium industries. In coatings, these fine powders deliver outstanding smoothness and gloss while reducing binder consumption. In plastics, ultrafine fillers contribute to better surface appearance and improved physical properties without negatively affecting flow behavior.

Liming Heavy Industry's ultrafine grinding mills feature precision classifiers, robust grinding chambers, and efficient airflow systems that ensure product quality and consistency. These mills are particularly suitable for Indian companies seeking to enter higher-end markets or differentiate their products on performance rather than price alone.

Key Factors in Equipment Selection

Selecting the right calcium carbonate grinding mill involves evaluating several critical factors beyond basic grinding capability. These include production capacity, energy consumption, maintenance requirements, raw material hardness and moisture content, and the flexibility to adjust fineness as market demands change.

Production Capacity – Manufacturers must match mill capacity to production needs. Underestimating capacity leads to bottlenecks, while oversizing increases capital cost without proportional benefit.

Energy Efficiency – Grinding is energy intensive. Choosing a mill with high efficiency reduces electricity costs and improves overall profitability.

Maintenance and Wear – Equipment that is easy to maintain and uses durable wear components minimizes downtime. Mills from Liming Heavy Industry are designed for accessible maintenance and long component life, addressing common challenges faced by Indian manufacturers.

Fineness Flexibility – Market demands change. A mill that allows quick adjustment of product fineness gives manufacturers the flexibility to serve different sectors without major equipment changes.

Environmental Considerations – Dust control and emissions are important in manufacturing facilities. Systems with effective sealing, dust collection, and clean operation support regulatory compliance and healthier workplaces.

Choosing Liming Heavy Industry as Your Partner

Liming Heavy Industry has a proven track record in supplying grinding solutions that match industrial requirements in India and beyond. Whether a manufacturer needs a cost-effective Raymond mill, a high-capacity vertical roller mill, or an advanced ultrafine grinding mill, Liming offers equipment engineered for reliability, flexibility, and consistent performance.

From initial consultation and plant design to installation and after-sales support, Liming Heavy Industry works closely with customers to ensure that grinding systems are tailored to specific raw material characteristics and product specifications. This hands-on approach helps reduce commissioning time, optimize production flow, and achieve stable quality output.

With an increasing focus on product differentiation and quality in India's plastic, paint, and coating sectors, choosing the right grinding mill is more than a technical decision—it is a strategic investment. By selecting equipment from Liming Heavy Industry, manufacturers gain access to technology that enhances competitiveness, improves operational efficiency, and supports long-term growth.

FAQs

What fineness of calcium carbonate is ideal for paint applications?

For most paint applications, particle sizes below 5 µm are preferred, and ultrafine grades below 2 µm deliver superior opacity, smoothness, and coverage.

Can a Raymond mill produce calcium carbonate for high-end plastics?

Raymond mills can produce fillers for general plastic applications, but ultrafine grinding mills are better suited for high-end polymer composites requiring very fine and uniform particles.

Why choose a vertical roller mill over a traditional ball mill?

Vertical roller mills integrate grinding, drying, and classification, offer higher efficiency, lower energy consumption, and consistent product quality for medium to large capacity operations.

How does particle shape affect coating performance?

Uniform and well-shaped particles improve packing density, reduce voids, and enhance surface finish, leading to better aesthetic and functional properties in coatings.

Is energy consumption important when choosing a grinding mill?

Yes, energy consumption significantly affects operating cost. More efficient mills reduce electricity usage and improve overall profitability.

What support does Liming Heavy Industry provide after equipment purchase?

Liming offers installation guidance, technical support, spare parts supply, maintenance training, and ongoing service to ensure continuous and stable operation.