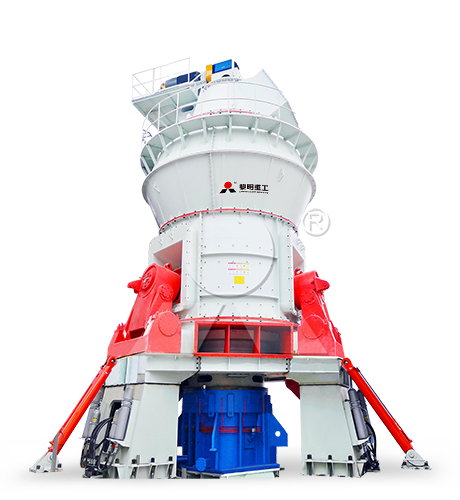

LM Vertical Slag Mill

Output Size: ≥420 m2/kg Capacity: 7-200 t/h

Introduction

LM Vertical slag mill, integrating drying, grinding, powder selection and conveying together, is a special equipment for grinding industrial waste into powder. It adopts a unique grinding device to achieve the integration of grinding and powder selection, focus on slag milling. The area is about 50% of the ball milling system. Energy consumption is 30% ~ 40% of the ball milling system.

Metallurgical slags: Blast furnace slag, steel slag, nickel residues, copper slag

Other materials: Slag cement, composite mixes, coal shale

Applications

It is widely used in the production of cement and concrete, as well as the recycling and milling of steel slag and water slag in steel plants.

Features

1. The vertical structure makes the covered area small. And it integrates many functions in one complete set.

2. The two processes of grinding and powder selection can be realized by one device, which can reduce investment costs a lot.

3. The important parts are made of good quality steel, and the wear-resistant parts are made of high-performance wear-resistant materials. The whole machine has advantages of high wear-resistant performance, reliable operation and long wearing parts, high efficiency.

4. The fineness of the finished powder is uniform and the screening rate is high.

5. There is relatively low noise during production.