Iron ore is an important raw material of steel manufacturers, after deep crushing and processing, it can be widely used in coating, chemical industry, electric, etc. Iron exist in nature all in compounds state, especially in the state of iron oxide but has more impurities. Such as hematite, magnetite, siderite, limonite, etc.

Process Description

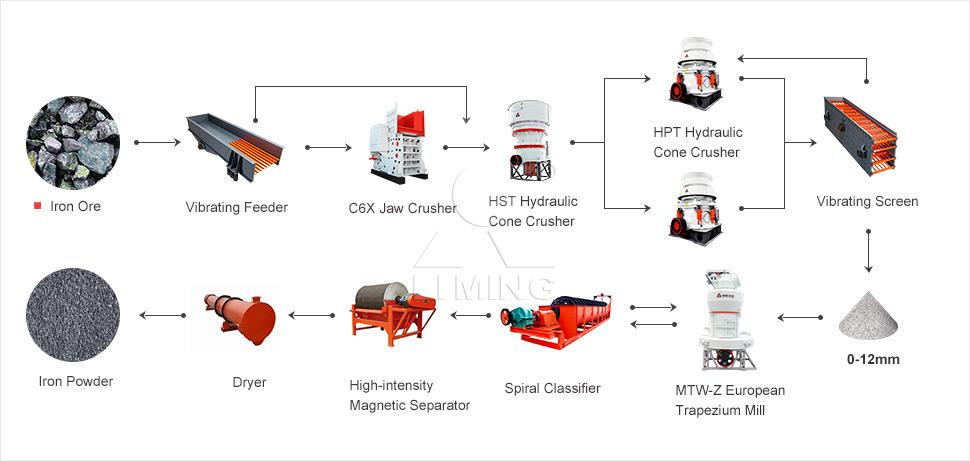

Pure magnetite can be directly input to the furnace for iron making, but there are still many associated ore. After all, some magnetite with high impurity content should be simply crushed and sieved, and magnetic ore grinding is used to produce concentrate, so Iron ore processing and production processes mainly include three processes: crushing, grinding, and beneficiation.

The first stage: crushing and screening-three-stage closed-circuit crushing

Large pieces of iron ore are evenly fed into the jaw crusher or coarse crushing mobile station by the feeder in the silo for coarse crushing; the coarsely crushed iron ore is screened by a vibrating screen and sent by a belt conveyor. Single-cylinder hydraulic cone crusher performs medium crushing; medium-crushed iron ore materials are sent to multi-cylinder hydraulic cone crusher for fine crushing.

The second stage: grinding

The 0-12 mm iron powder sieved by the vibrating screen is uniformly sent to the mill for milling, and is screened by a spiral classifier. If it does not meet the requirements, it is sent to the mill to continue milling.

The third stage: magnetic separation

Send iron powder that meets the requirements for beneficiation into a magnetic separator for strong magnetic separation and magnetic separation to remove debris.

The fourth stage: drying

The obtained iron powder is sent to a dryer for drying to obtain iron fine powder.