Manganese ore is a fine-grained or fine-grained intercalation, and has a considerable amount of high-phosphorus ore, high-iron ore, and symbiotic non-ferrous metals, which brings great difficulties to the processing of manganese ore. At present, the commonly used manganese ore dressing equipment mainly includes ore washing, screening, gravity separation, strong magnetic separation and flotation.

Process Description

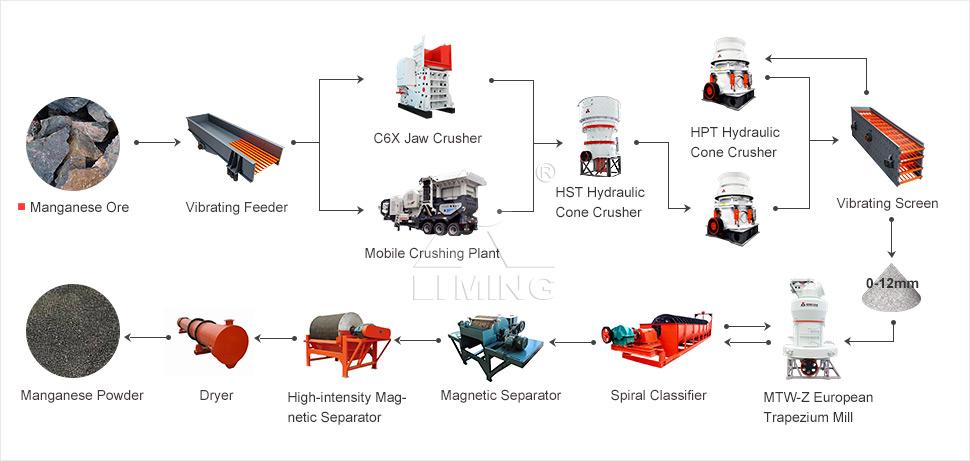

Nowadays, the manganese ore processing mainly includes crushing, grinding and beneficiation. Generally, the ore is crushed to 6 ~ 0mm or 10 ~ 0mm, and then grouped. The coarse grades are eliminated and fine grades are sent for table concentration. At present, the commonly used crushing equipment is a jaw crusher. The crushed manganese ore is milled by a longitudinal milling machine to obtain the finished products of various specifications, and then the appropriate beneficiation process is used for beneficiation.

The first stage: crushing and screening — three-stage closed-circuit crushing

Large pieces of manganese ores are evenly sent to the jaw crusher or coarse mobile crusher station by the feeder through the silo for coarse crushing. The coarsely crushed manganese ores are screened by a vibrating screen and sent by a belt conveyor to the single cylinder hydraulic cone crusher for medium crushing. The manganese ores after medium crushing are sent to multi-cylinder hydraulic cone crusher for fine crushing.

The second stage: grinding

The 0-12mm manganese powder that has been screened by a vibrating screen is evenly sent to a mill for milling, and is screened by a spiral classifier. If it does not meet the requirements, it is sent to the mill to continue milling.

The third stage: beneficiation

The manganese powder that meets the requirements is sent to a magnetic separator for strong magnetic separation to remove impurities, and the obtained manganese powder is sent to a dryer for drying to obtain manganese fine powder.