Copper ore, hardness of 3-4, copper ore after smelting commission becomes refined copper and copper products. Concentrate copper ore species: native copper, chalcopyrite, bornite, chalcocite, azurite and covellite. Copper ore is mainly used in metallurgical industry, metallurgical industry raw material.

Process Description

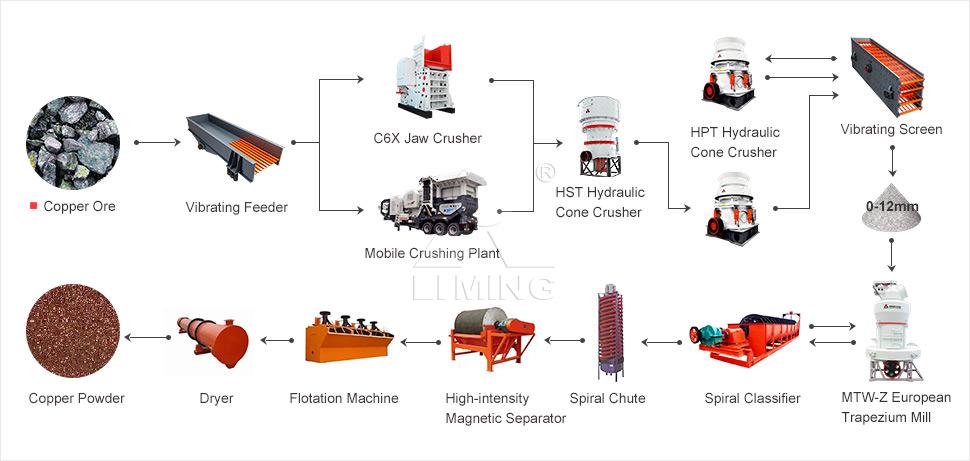

Copper ore processing and production technology mainly includes three processes: crushing, grinding and beneficiation. During the crushing process, the three-stage closed-circuit crushing is a modern method suitable for the crushing of high-hardness copper ore. It can complete the ore crushing and partial dissociation work, thereby improving the subsequent grinding efficiency. During the grinding process, the second stage has one closed grinding. It can make the copper ore grinding more fully; in the ore dressing process, the more successful new process that has appeared in recent years is typically a mixed flotation process.

The first stage: crushing and screening-three-stage closed-circuit crushing

Large pieces of copper ore are evenly fed into the jaw crusher or coarse crushing mobile station by the feeder in the silo for coarse crushing; the coarsely crushed copper ore is screened by a vibrating screen and sent by a belt conveyor. Single-cylinder hydraulic cone crusher performs medium crushing; medium-crushed copper ore materials are sent to multi-cylinder hydraulic cone crusher for fine crushing.

The second stage: grinding

The 0-12 mm copper powder sieved by the vibrating sieve is uniformly sent to the ball mill for milling, and is screened by a spiral classifier. If it does not meet the requirements, it is sent to the mill to continue milling.

The third stage: beneficiation-a new process of flotation

The copper powder that meets the requirements is sent to a flotation machine for mixed flotation, and the obtained copper powder is sent to a dryer for drying to obtain copper fine powder.